![]() Print Version | Flyer | Request Literature / Sample | Safety Data Sheet | Guide Specification

Print Version | Flyer | Request Literature / Sample | Safety Data Sheet | Guide Specification

SOUND-ABATE™

Acoustical Shielding for Wall Applications

DESCRIPTION

SOUND-ABATE is a mass loaded, limp vinyl sound damping material designed for commercial, industrial, and residential applications to reduce sound transmission.

SOUND-ABATE is a mass loaded, limp vinyl sound damping material designed for commercial, industrial, and residential applications to reduce sound transmission.

USES

SOUND-ABATE is designed for installation behind gypsum drywall, finished surfaces to block and dampen sound transmission through the entire sound frequency spectrum.

APPLICATION

Place SOUND-ABATE sheet in position at top of the wall. Align vertical edges over center of studs. Insert staples along top edge of sheet to hold in place. Allow SOUND-ABATE to unroll vertically along the height of the wall. Apply additional staples along vertical edge if desired. For each additional sheet of SOUND-ABATE to be installed, repeat the previous procedure. Note: Ensure vertical seems center over studs. Trim sheet if necessary. Locate any wall outlet penetrations that will require access and cut an X access point for each. Caulk floor, ceiling, and corner joints before installing drywall.

Steel Stud Installation … For installation of SOUND-ABATE Mass Loaded Vinyl sheets over steel studs, follow installation procedures for wood studs and replace staples with self-tapping, flat head metal screws.

Steel Stud Installation … For installation of SOUND-ABATE Mass Loaded Vinyl sheets over steel studs, follow installation procedures for wood studs and replace staples with self-tapping, flat head metal screws.

FEATURES/BENEFITS

- Dampens sound and blocks noise by up to 75%.

- Easy to install – reduces labor and production costs.

- Thin profile saves material and labor with no added extensions or adjustments

- Improves HVAC efficiency.

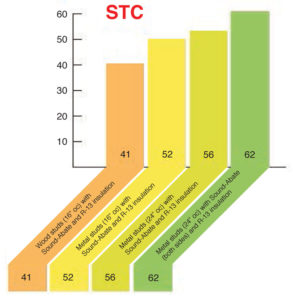

- One layer improves STC rating by 7 in typical wood and steel studded assemblies (16″ o.c., R13 batt insulation, and 5/8″ gypsum drywall)

- Classified by Underwriters Laboratories, Inc. as to ANSI/UL 263 Standard, Fire Tests of Building Construction and Materials, UL File CLBV.R39387

- UL Classified in fire resistant wall designs of the U300, U400, and V400 series.

TECHNICAL DATA

| Roll size = 0.10″ x 4′ x 25′ (100 sf) at 100 lbs |

| Surface weight = 1.0 lb/sf |

| Material = EVA, Ethylene vinyl acetate copolymer |

| Contains no PVC |

| No VOC content, no off-gassing |

| One hour fire resistance assembly rated per ASTM E 119 |

| Does not support mold growth |

| Highest Mold Resistance Rating = 10 Per ASTM D3273 |

| STC 26 per ASTM E 90 |

| Class C Flame Spread per ASTM E 84 |

| Flame Spread Index 140 Smoke Developed 250 |

| R Value ≥ 0.3 |

MASTERFORMAT NUMBER AND TITLE

09 81 00 – Acoustic Insulation

09 81 13 – Acoustic Board Insulation

13 48 00 – Sound, Vibration, and Seismic Control

LEED v3/2009 and LEED v4 Cross Reference Table

| LEED v3/2009 New Construction | LEED v4 Building Design & Construction (LEED BD+C) |

| MR Credit 2: Construction Waste Management | MR Credit: Construction and Demolition Waste Management |

| MR Credit 5: Regional Materials | MR Credit: Building Product Disclosure and Optimization – Environmental Product Declaration |

| IEQ Prerequisite 3: Minimum Acoustical Performance (Schools) | EQ Prerequisite: Minimum Acoustic Performance (Schools) |

| IEQ Credit 4.4: Low-Emitting Materials | EQ Credit: Low-Emitting Materials |

| IEQ Credit 9: Enhanced Acoustical Performance (Schools) | EQ Credit: Acoustic Performance |

| IEQ Credit 10: Mold Prevention (Schools) | EQ Credit: Indoor Environmental Quality, Thermal Comfort |

| ID Credit 1: Innovation in Design | IN Credit: Innovation |

2018-02