![]() Print Version | Flyer | Safety Data Sheet | Guide Specification

Print Version | Flyer | Safety Data Sheet | Guide Specification

Installation Guidelines | Testimonials | Request Literature/Sample

STOMP™

Acoustical Shielding for Floor & Wall Applications

DESCRIPTION

STOMP acoustical shielding is a limp, high density acoustical grade polymer sheet material, formulated from environmentally friendly, polyolefin elastomer (POE). STOMP is a high quality, cost effective sound damping material designed to reduce sound transmission.

USES

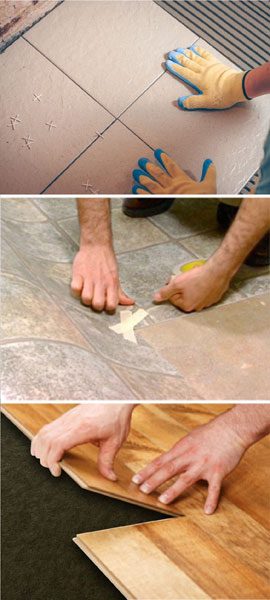

STOMP is designed for use in both floor and wall applications to reduce both impact and airborne noise. It is appropriate for commercial, industrial, and residential applications. STOMP’s design combines a dense and flexible POE sheet layer with a fibrous isolation layer.

FEATURES/BENEFITS

- For use in walls directly behind gypsum drywall; and in flooring applications directly under carpet, LVT, wood, engineered wood, and laminate floorings

- Increases Impact Insulation Class (IIC) and Sound Transmission Class (STC) ratings of floor/ceiling and wall assemblies

- Dampens sound and blocks noise

- Easy to install – reduces labor and production costs

- Thin profile saves material and labor with no added extensions or adjustments

- Improves HVAC efficiency

- Classified by Underwriters Laboratories, Inc. as to ANSI/UL 263 Standard, Fire Tests of Building Construction and Materials, UL File CLBV.R39387 Wall and Partition Facings and Accessories.

- UL Classified in fire resistant wall designs of the U300, U400, and V400 series

- UL Classified in fire resistant floor-ceiling constructions of the L500 series

- Made in the USA

PACKAGING

4′ x 25′ (1.2 x 7.6 m) Rolls (one roll per box)

TECHNICAL DATA

| Description: Black mass loaded POE layer with a black or brown fibrous polyester isolation layer. |

| Roll size: 4′ (1,219 mm) x 25′ (7,620 mm) |

| Thickness (Nominal): 3/16″ (4.75 mm) |

| Surface Weight: 0.8 lb/sf (nominal) |

| Material: POE, Polyolefin elastomer, contains no PVC |

| Flame Spread Index: Class C, 140 FSI per ASTM E84 |

| Smoke Developed Index: 250 SDI per ASTM E84 |

| Sound Transmission Class (STC): 25 per ASTM E90 |

| Thermal Resistance (R- value): 0.796 |

| Fire Resistance: Hourly rated in wall and floor/ceiling assemblies per ASTM E 119 and ANSI/UL263 |

| Resistance to Mold Growth, ASTM D3273 and G21, highest resistance rating of 10, no visible growth |

| Water Vapor Transmission: <0.50 perms, ASTM E96 |

APPLICATION

FLOORS

Position STOMP with fibrous polyester side down onto the floor. Place edge to edge multiple sheets of STOMP to complete the coverage of the room being treated.

Add desired flooring on top of STOMP as per recommended installation techniques. Carpet and laminate floors can be installed directly on top. Wood floors can be nailed directly on top. Laminate floors can be floated directly on top.

Recommended for use with LVT 5 mm and thicker.

Not designed for use under ceramic, porcelain, or VCT tile.

WALLS

Place STOMP sheet in position at top of the wall with black POE side against studs in new construction, and fibrous polyester side against existing walls. Align vertical edges over center of studs. Insert staples along top edge of sheet to hold in place. Allow STOMP to unroll vertically along the height of the wall. Apply additional staples along vertical edge if desired. For each additional sheet of STOMP to be installed, repeat the previous procedure.

Note: Ensure vertical seems are centered over studs. Trim sheet if necessary. Locate any wall outlet penetrations that will require access and cut an X access point for each. Caulk floor, ceiling, and corner joints before installing drywall.

Steel Stud Installation … For installation of STOMP sheets over steel studs, follow installation procedures for wood studs and replace staples with self-tapping, flat head metal screws.

MASTERFORMAT NUMBER AND TITLE

09 81 00 – Acoustic Insulation

09 81 13 – Acoustic Board Insulation

13 48 00 – Sound, Vibration, and Seismic Control

2023-03